Iinkcukacha

I-SILIKE Si-TPV 2150 Series yi-elastomer esekwe kwi-silicone eguquguqukayo, eyenziwe kusetyenziswa ubuchwepheshe obuphambili bokuhambelana. Le nkqubo isasaza irabha ye-silicone kwi-SEBS njengamasuntswana amancinci, ukusuka kwi-1 ukuya kwi-3 microns phantsi kwe-microscope. Ezi zinto zikhethekileyo zidibanisa amandla, ukuqina, kunye nokumelana nokukrala kwe-thermoplastic elastomers kunye neempawu ezinqwenelekayo ze-silicone, ezinje ngokuthamba, ukuvakala kwesilika, kunye nokumelana nokukhanya kwe-UV kunye neekhemikhali. Ukongeza, izinto ze-Si-TPV zinokuphinda zisetyenziswe kwaye zinokusetyenziswa kwakhona kwiinkqubo zemveli zokuvelisa.

I-Si-TPV ingasetyenziswa ngokuthe ngqo njengezinto eziluhlaza, ezenzelwe ngokukodwa ukusetyenziswa kokubumba okuthambileyo kwii-elektroniki ezinxitywayo, iikheyiji zokukhusela izixhobo ze-elektroniki, izinto zeemoto, ii-TPE eziphezulu, kunye namashishini eentambo ze-TPE.

Ngaphandle kokusetyenziswa kwayo ngokuthe ngqo, i-Si-TPV ingasebenza njengesilungisi se-polymer kunye nesithako senkqubo kwi-thermoplastic elastomers okanye ezinye ii-polymers. Iphucula ukuthamba, iphucula ukucubungula, kwaye iphucula iipropati zomphezulu. Xa ixutywe ne-TPE okanye i-TPU, i-Si-TPV inika ukuguda komphezulu okuhlala ixesha elide kunye nemvakalelo emnandi yokuchukumisa, ngelixa iphucula ukukrwela kunye nokukrwela. Inciphisa ubulukhuni ngaphandle kokuchaphazela kakubi iipropati zoomatshini kwaye inika ukuguga okungcono, ukutyheli, kunye nokumelana namabala. Inokwenza nokugqitywa okunqwenelekayo komphezulu.

Ngokungafaniyo nezongezo ze-silicone eziqhelekileyo, i-Si-TPV ifumaneka kwimo ye-pellet kwaye icutshungulwa njenge-thermoplastic. Isasazeka kakuhle kwaye ifana kuyo yonke i-polymer matrix, apho i-copolymer ibotshelelwa ngokwasemzimbeni kwi-matrix. Oku kususa inkxalabo yokufuduka okanye imiba "yokuqhakaza", okwenza i-Si-TPV ibe sisisombululo esisebenzayo nesinobuchule sokufezekisa iindawo ezithambileyo zesilika kwi-thermoplastic elastomers okanye ezinye ii-polymers. kwaye ayifuni amanyathelo ongezelelweyo okucubungula okanye okufaka.

Iingenelo eziphambili

- Kwi-TPE

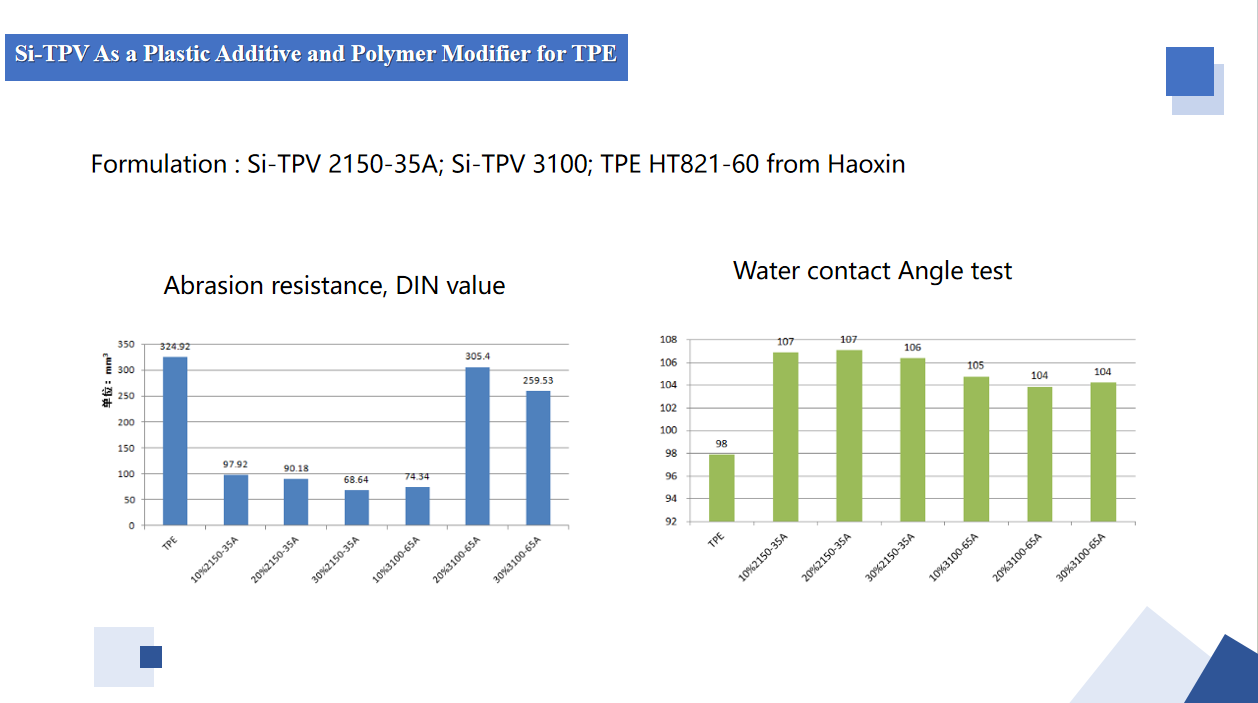

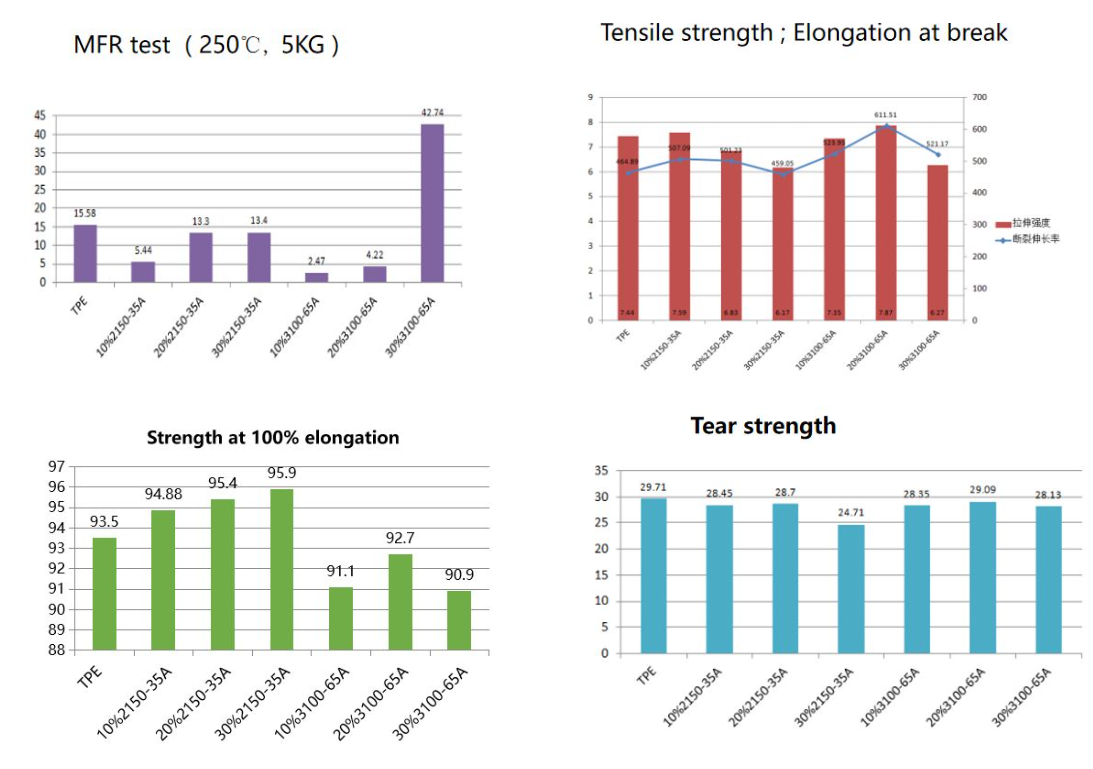

- 1. Ukumelana nokurhawuzelelwa

- 2. Ukumelana namabala nge-engile encinci yokudibana namanzi

- 3. Nciphisa ubulukhuni

- 4. Akukho mpembelelo phantse kwiipropati zoomatshini ngothotho lwethu lwe-Si-TPV 2150

- 5. Ii-haptics ezintle kakhulu, ukuchukumisa okomileyo okuthambileyo, akukho kuqhakaza emva kokusetyenziswa ixesha elide

Ukuqina Uzinzo

- Itekhnoloji ephucukileyo engenazinyibilikisi, ayinaplastiki, ayinaoyile yokuthambisa, kwaye ayinavumba.

- Ukukhuselwa kwendalo kunye nokuphindeka kwayo.

- Ifumaneka kwiifomyula ezithobela imithetho.

Izifundo zeTyala zeSi-TPV zeplastiki kunye ne-polymer modifier

I-Si-TPV 2150 series ineempawu zokuchukumisa ulusu ixesha elide, ukumelana namabala, akukho plasticizer kunye nesithambisi esongeziweyo, kwaye akukho mvula emva kokusetyenziswa ixesha elide, esebenza njengesongezelelo seplastiki kunye nesiguquli sepolymer, ngakumbi esetyenziselwa ukulungiselela i-elastomers ye-thermoplastic ethambileyo nethambileyo.

Ukuthelekisa Iziphumo zeSi-TPV Plastic Additive kunye nePolymer Modifier kwiNtsebenzo yeTPE

Isicelo

I-Si-TPV isebenza njengesilungisi semvakalelo esitsha kunye nesincedisi sokucubungula ii-elastomers ze-thermoplastic kunye nezinye iipolymers. Ingadityaniswa nee-elastomers ezahlukeneyo kunye nobunjineli okanye iiplastiki eziqhelekileyo, ezifana ne-TPE, i-TPU, i-SEBS, i-PP, i-PE, i-COPE, i-EVA, i-ABS, kunye ne-PVC. Ezi zisombululo zinceda ukuphucula ukusebenza kakuhle kokucubungula kunye nokuphucula ukusebenza kokukrwela kunye nokukrwela kwezinto ezigqityiweyo.

Inzuzo ephambili yeemveliso ezenziwe nge-TPE kunye ne-Si-TPV blends kukudala umphezulu othambileyo nongagungqiyo—ngokuchanekileyo amava achukumisayo abasebenzisi bokugqibela abawalindeleyo kwizinto abazichukumisayo okanye abazinxiba rhoqo. Olu phawu lukhethekileyo lwandisa uluhlu lwezicelo ezinokubakho zezinto ze-TPE elastomer kumashishini amaninzi. Ngaphezu koko, ukufaka i-Si-TPV njengesiguquli kuphucula ukuguquguquka, ukuthamba, kunye nokuqina kwezinto ze-elastomer, ngelixa kwenza inkqubo yokuvelisa ibe nexabiso eliphantsi.

Izisombululo:

Ngaba ulwela ukuphucula ukusebenza kwe-TPE? Izongezo zeplastiki ze-Si-TPV kunye nezilungisi ze-polymer zibonelela ngempendulo

Intshayelelo kwi-TPEs

Ii-elastomers ze-thermoplastic (TPEs) zahlulwe ngokweekhemikhali, kuquka ii-Thermoplastic Olefins (TPE-O), iiStyrenic Compounds (TPE-S), iiThermoplastic Vulcanizates (TPE-V), iiPolyurethanes (TPE-U), iiCopolyesters (COPE), kunye neeCopolyamides (COPA). Ngelixa ii-polyurethanes kunye neecopolyesters zinokulungiswa kakhulu ukuze zisetyenziswe kwezinye izinto, iindlela ezingabizi kakhulu ezifana ne-TPE-S kunye ne-TPE-V zihlala zibonelela ngokulungelelana okungcono kwezicelo.

Ii-TPE eziqhelekileyo zixubene ngerabha kunye ne-thermoplastics, kodwa ii-TPE-Vs zahlukile ngokuba namasuntswana erabha adityaniswe ngokuyinxenye okanye ngokupheleleyo, nto leyo ephucula ukusebenza kwazo. Ii-TPE-Vs zineeseti zoxinzelelo eziphantsi, ukumelana okungcono kweekhemikhali kunye nokukrala, kunye nozinzo oluphezulu lobushushu, nto leyo ezenza ukuba zilungele ukutshintsha irabha kwizitywini. Ngokwahlukileyo koko, ii-TPE eziqhelekileyo zibonelela ngokuguquguquka okukhulu kokwenziwa, amandla aphezulu okutsalwa, ukuthamba, kunye nombala, nto leyo ezenza zifaneleke kwiimveliso ezifana neempahla zabathengi, izixhobo ze-elektroniki, kunye nezixhobo zonyango. Zikwadibana kakuhle nezinto eziqinileyo ezifana ne-PC, i-ABS, ii-HIPS, kunye ne-Nylon, eluncedo kwiisicelo ezithambileyo.

Imingeni nge-TPE

Ii-TPE zidibanisa ukuthamba kunye namandla oomatshini kunye nokukwazi ukucutshungulwa, nto leyo ezenza zibe nokuguquguquka okukhulu. Iimpawu zazo zokuthamba, ezifana nokuseta ukucinezelwa kunye nokwandiswa, zivela kwisigaba se-elastomer, ngelixa amandla okutsalwa kunye nokukrazulwa axhomekeke kwinxalenye yeplastiki.

Ii-TPE zinokucutshungulwa njenge-thermoplastics eziqhelekileyo kumaqondo obushushu aphezulu, apho zingena kwisigaba sokunyibilika, okuvumela ukwenziwa okusebenzayo kusetyenziswa izixhobo zokucubungula iplastiki eziqhelekileyo. Uluhlu lwazo lobushushu bokusebenza nalo luyaphawuleka, ukusuka kumaqondo obushushu aphantsi kakhulu—kufutshane nendawo yokutshintsha kweglasi yesigaba se-elastomer—ukuya kumaqondo obushushu aphezulu asondela kwinqanaba lokunyibilika lesigaba se-thermoplastic—okongeza kwintsebenzo yazo eguquguqukayo.

Nangona kunjalo, nangona ezi zibonelelo zilungile, imingeni emininzi isaqhubeka ekwenzeni ngcono ukusebenza kwee-TPE. Ingxaki enkulu kukuba kunzima ukulinganisela ukuthamba kunye namandla oomatshini. Ukuphucula ipropati enye kudla ngokubiza enye, okwenza kube nzima kubavelisi ukuphuhlisa iifomyula ze-TPE ezigcina ulungelelwano oluhambelanayo lweempawu ezifunwayo. Ukongeza, ii-TPE zisengozini yokonakala komphezulu njengemikrwelo kunye nokubola, okunokuchaphazela kakubi inkangeleko kunye nokusebenza kweemveliso ezenziwe ngezi zinto.